Glass fabricators, or glass cutting manufacturers, produce a wide range of glass types and glass products. These types of glass can be used for numerous purposes (such as protection, insulation, containment,) and for numerous types of products (such as optical and laboratory equipment). Since glass has varied strength as well as transparent and heat-resistant properties, it is a prominent material in manufacturing and other industries. Read More…

S & S Optical has been leaders as glass fabricators in a variety of industries and markets for over 50 years. We offer a variety of different glasses to fit all of your needs. Also, we have a multitude of capabilities and services to offer-polishing, grinding, edging and more. To learn how we can fabricate your parts contact us today for a quote. We care about customers and quality service.

Established in 1947, we have been providing glass cutting using very precise tolerances in order to ensure that our products are among the best. Our skilled designers and technicians are available around the clock in order to work with you from design to delivery to ensure that you are receiving a product that will fit your needs perfectly! For more information on what we may be able to do for...

Founded in 1990, Technical Glass Products is a fabricator of Fused Quartz Glassware. We maintain a broad inventory of labware, flat stock, rod and tubes in addition to providing custom fabrication using state of the art equipment to suit your needs.

Glass cutting is a varied industry, and we have done it all for the past 50 years. We believe in manufacturing high quality glass products that will exceed customer expectations every time.

More Glass Fabrication Companies

Glass Characteristics and Material Properties

Glass is a remarkable engineering material that sets itself apart from metals, ceramics, and plastics due to its unique combination of physical and chemical properties. As an inorganic, amorphous solid, glass exists in a state that blends fluidity with rigidity: its internal atomic structure is disordered like a liquid, yet externally, it behaves with the hardness and brittleness characteristic of solids. This duality gives glass its signature qualities, making it indispensable in a range of industrial and architectural applications.

The defining attributes of glass stem from its precise chemical composition and the advanced manufacturing techniques used in its production. In essence, glass is made from a carefully measured blend of dry minerals—collectively known as a “batch”—which undergoes a controlled heating and cooling process to develop the desired non-crystalline molecular structure. The batch consists of a former (main mineral component), flux (to lower melting temperature), and stabilizers (to enhance chemical durability and prevent dissolution).

Silica (silicon dioxide) is the primary base material in most glass fabrication processes. Sodium carbonate (soda ash) is commonly used as a flux to reduce silica’s extremely high melting point from 4172°F to a more manageable 2732°F, while calcium oxide (from limestone) serves as a stabilizer to reinforce the glass’s structural integrity. Depending on the intended product and performance requirements, other additives such as magnesium oxide, gypsum, aluminum oxide, and dolomite may be introduced at various stages, further tailoring the glass’s optical, mechanical, and chemical properties.

Glass’s material properties—such as transparency, hardness, resistance to chemical attack, and electrical insulation—make it suitable for demanding applications in electronics, laboratory equipment, and architectural glazing. Its ability to be customized at the molecular level allows for the development of specialty glasses with enhanced strength, UV resistance, or thermal stability, expanding the scope of what glass can achieve in modern industry.

What is Glass Fabrication?

Glass fabrication refers to a comprehensive suite of processes that transform raw glass into finished products with specific shapes, features, and performance characteristics. These processes are critical in industries ranging from construction and automotive manufacturing to electronics, optics, and consumer goods.

The glass fabrication process begins with cutting—the division of large glass sheets or blocks into desired dimensions. This can be achieved using mechanical scoring and breaking, or advanced technologies like laser cutting and waterjet cutting for precision and complex geometries. Next comes grinding, which refines and shapes the edges or surfaces of the glass, producing smooth finishes and preparing the material for further processing.

Drilling involves the use of diamond-coated drill bits to create clean, accurate holes in glass, enabling hardware mounting or specialized applications such as laboratory glassware. Polishing follows, utilizing fine abrasives to achieve a flawless, glossy surface free from scratches or imperfections. Tempering is a heat treatment that greatly increases the mechanical strength and thermal resistance of glass, making it ideal for safety-critical applications like doors, windows, and shower enclosures.

Additional finishing processes—such as painting, coating, sandblasting, and decorative etching—further expand the functional and aesthetic possibilities of glass. Edging is especially important for safety and usability, removing sharp edges to prevent injuries and ensuring a professional appearance. Each fabrication technique delivers distinct benefits: customization and reduced waste (cutting), precise shaping (grinding), integration of hardware (drilling), aesthetic enhancement (polishing), strength and safety (tempering), creative design (finishing), and user protection (edging).

Together, these fabrication methods enable the production of glass products tailored for architectural glazing, automotive safety glass, laboratory instruments, consumer electronics, and artistic installations. The versatility of glass fabrication supports a broad spectrum of buyer intents—from custom architectural solutions to mass-produced components for industrial and technological applications.

History of Glass

The origins of glass trace back to prehistoric times and are often attributed to accidental discoveries—such as the fusion of minerals during volcanic eruptions or lightning strikes, which occasionally produce natural glass like obsidian. Early civilizations, including the Phoenicians, Mesopotamians, and Egyptians, were among the first to recognize the value of this material, using glass for decorative beads, amulets, and simple vessels.

By the first century BC, the innovation of glassblowing by Phoenician artisans revolutionized glass production, allowing for the creation of intricate shapes and larger vessels. Romans further advanced glass technology, introducing it into architecture by installing glass windows in significant buildings. The demand for glass containers to preserve food and liquids drove further expansion and sophistication in glassmaking during antiquity.

Glass production experienced cycles of growth and decline throughout history. A major revival took place in northern Italy during the Renaissance, particularly on the island of Murano, which became synonymous with high-quality decorative glass. In the New World, glassmaking was one of the earliest industries established in the English colony of Jamestown (1608/1609), although it would take until the founding of the first permanent glass plant by Casper Wister in 1739 for the industry to gain a stable foothold in America. The advent of glass pressing in the 1820s ushered in a new era of mass production, making glass more affordable and accessible.

The 20th and 21st centuries have seen unprecedented advancements in glass science and technology. Modern innovations such as laminated glass, tempered safety glass, float glass production, and specialty coatings have expanded the use of glass in construction, transportation, electronics, and renewable energy. Today, glass can be engineered to be fire-resistant, bulletproof, UV-blocking, or even self-cleaning, underscoring its enduring importance in contemporary society.

How Glass is Made

Modern glass production begins with the careful formulation of the batch—a blend of silica, fluxes, stabilizers, and optional additives. This mixture is melted in a furnace at temperatures that can exceed 2400°F, producing a homogenous, molten material. Maintaining the correct ratio of ingredients is crucial; improper composition may result in defects such as “crizzling” (fine surface cracking) or chemically unstable glass.

Customization of glass properties starts during the batch stage through the addition of various metallic oxides and colorants. For example, iron oxide produces green hues, copper oxide imparts blue, gold can create rich reds, and cobalt yields deep blues. Manganese dioxide not only colors glass but can also decolorize it, effectively neutralizing unwanted tints in recycled glass.

Once fully melted, the molten glass is formed into products using methods such as pressing, molding, and blowing. Pressing involves shaping glass with molds to create items like bricks and blocks. Molding is used for complex or decorative shapes, while glassblowing—either by hand or machine—enables the creation of bottles, laboratory glassware, and art pieces. Automated glassblowing, using high temperatures and mechanical forming, is a mainstay in large-scale container manufacturing.

The float glass process is a key innovation in the production of flat glass for windows, mirrors, and solar panels. In this method, molten glass is floated on a bath of molten tin, allowing gravity and surface tension to produce perfectly flat, uniform sheets. The thickness of the glass is controlled by the speed at which it is drawn off the bath onto rollers.

A critical phase in glassmaking is annealing, or controlled cooling. This process relieves internal stresses developed during shaping, preventing warping or spontaneous breakage. Annealing is typically performed in a lehr (a specialized oven) or on conveyor systems for large glass panels. The resulting flat glass is the starting point for further finishing and fabrication.

Glass can be further strengthened through reheating and rapid cooling, a process known as tempering. Depending on the rate and intensity of cooling, glass may become heat-strengthened (semi-tempered) or fully tempered (toughened), with corresponding increases in impact resistance and safety performance. Laminated glass is produced by bonding layers with resin interlayers, such as polyvinyl butyral (PVB), enhancing its ability to withstand impact and prevent shattering.

Cutting and shaping glass for final use involves specialized tools and advanced technologies. Traditional glass cutters score the surface, allowing the glass to be snapped along the score line. Waterjet cutting—a modern, precise method—uses a high-pressure stream of water mixed with abrasives like garnet or olivine to slice through glass without generating heat or dust. This technique enables intricate patterns and complex shapes, ideal for custom architectural elements and industrial components.

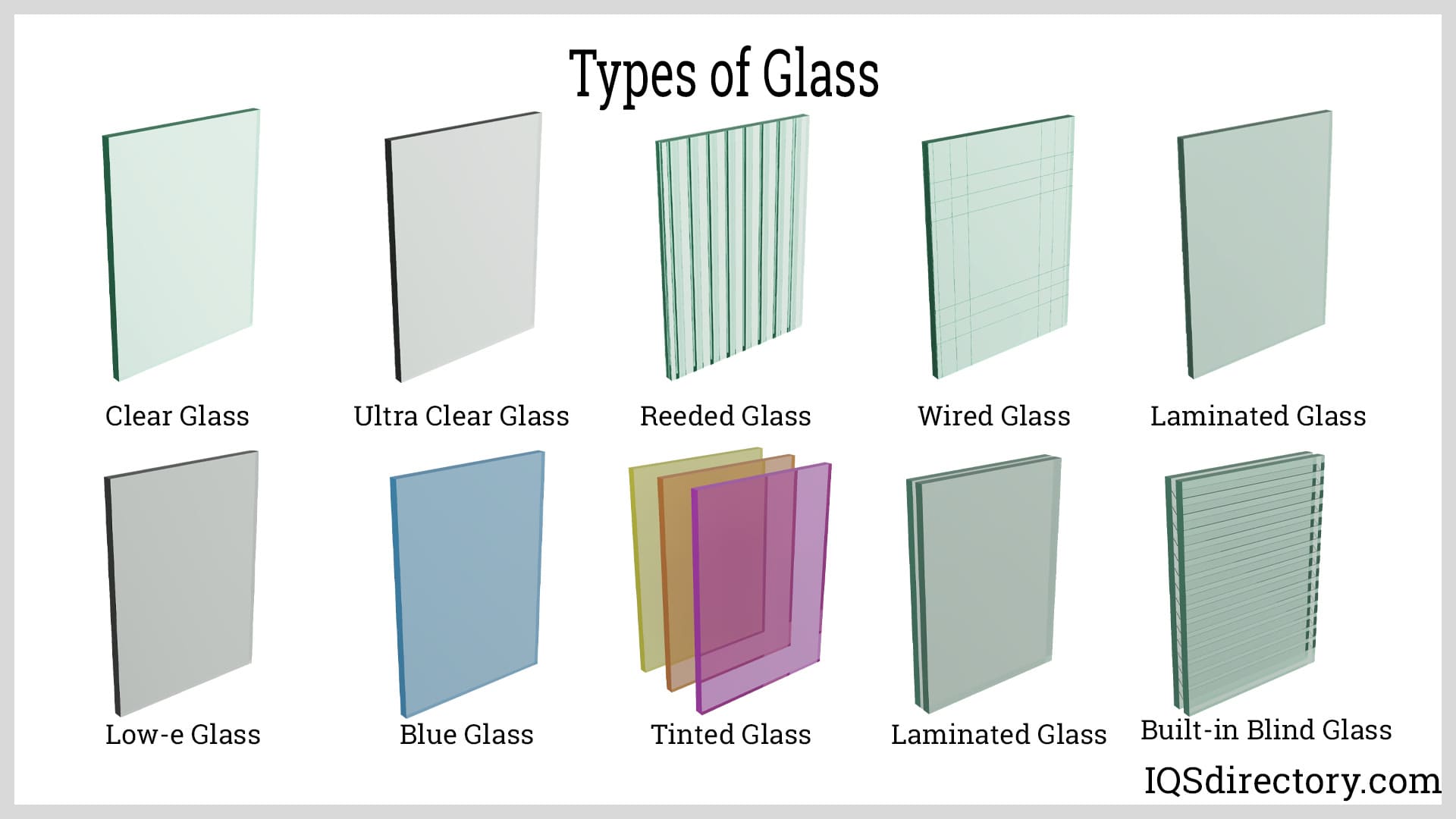

Types of Glass

The diversity of glass products is reflected in the variety of glass types, each formulated for specific performance requirements. Glass is generally classified according to its chemical composition and intended application.

Fused silica, fused quartz, or quartz glass is the purest form of glass, composed solely of silicon dioxide. It offers exceptional thermal resistance and optical clarity, making it essential for high-temperature and ultraviolet (UV) applications in laboratories, optics, and electronics.

Soda-lime glass is the most widely used glass type, consisting of silica, soda ash, and lime. It is valued for its cost-effectiveness and versatility, serving as the foundation for window glass, beverage bottles, and food containers.

Lead glass, commonly referred to as crystal, contains substantial amounts of lead oxide. This enhances its refractive index and brilliance, making it ideal for fine glassware, optical components, and radiation shielding.

Borosilicate glass—known by trade names like Pyrex—contains boron oxide, which confers outstanding resistance to thermal shock and chemical corrosion. It is used extensively in laboratory glassware, kitchen cookware, and lighting. Ninety-six percent silica glass is a specialized form of borosilicate glass with superior thermal properties, achieved by removing virtually all non-silicate elements.

Aluminosilicate glass incorporates aluminum oxide for enhanced durability and high-temperature performance. It is used in demanding environments such as electronic components, aerospace, and advanced optics, where resistance to thermal expansion and chemical attack is paramount.

Specialty glasses include low iron glass (water clear or starphire glass) for maximum transparency, wire glass for fire-resistance and reinforcement, and fiberglass, composed of fine glass fibers embedded in a polymer matrix, widely used in insulation, composites, and structural panels.

Are you searching for the best type of glass for high-performance applications? Explore our comprehensive directory of glass fabricators to compare options and request a quote tailored to your specifications.

Advantages of Glass

Glass is prized across industries not just for its aesthetic value but also for its functional superiority. If you’re evaluating materials for your next project, consider the following unique benefits of glass:

- Exceptional Strength: Despite its lightweight nature, glass can be engineered for remarkable strength. Surface flaws are the main cause of breakage, but processes like tempering and lamination greatly improve its resistance to impact and stress.

- Chemical and Thermal Resistance: Glass offers outstanding resilience to abrasion, chemical exposure, high temperatures, and electric currents, making it ideal for laboratory, industrial, and high-voltage electrical applications.

- Optical Clarity and Light Transmission: Glass excels at transmitting visible light with minimal distortion, making it the material of choice for windows, lenses, and display panels. Its ability to absorb, reflect, or filter specific wavelengths is exploited in advanced optics and energy-efficient construction.

- Customizability and Workability: Glass can be intricately carved, etched, molded, and colored, enabling limitless possibilities for creative and functional design—from artistic installations to precision-engineered components.

- Low Maintenance and Durability: Properly selected and fabricated glass is low-maintenance, retaining its appearance and performance for decades with minimal upkeep.

- Sustainability and Recyclability: Glass is made from abundant natural materials and can be recycled indefinitely without loss of quality, supporting eco-friendly construction and manufacturing initiatives.

Still unsure if glass is right for your project? Contact a glass fabrication expert to discuss your unique requirements and explore custom solutions.

Applications of Glass Products

Glass products are integral to a multitude of sectors, reflecting their versatility and adaptability. Whether you are a manufacturer seeking durable components or a designer aiming for aesthetic brilliance, glass offers solutions for both standard and specialized applications.

In the construction industry, glass is vital for architectural glazing, curtain walls, skylights, and interior partitions, contributing to energy efficiency, daylighting, and modern aesthetics. Float glass is the standard for residential and commercial windows, while laminated and tempered glass provide enhanced safety and security in high-traffic areas and hurricane-prone regions.

The automotive sector relies on precision-fabricated glass for windshields, side and rear windows, sunroofs, and mirrors. Safety glass—produced through tempering and lamination—ensures that, in the event of breakage, glass fragments remain blunt and less likely to cause injury.

In industrial and laboratory settings, glass is indispensable for sight glasses, laboratory beakers, test tubes, and chemical reactors. Sight glass enables the real-time monitoring of processes, while borosilicate and quartz glass withstand extreme temperatures and aggressive chemicals.

The electronics and optics industries leverage glass for display panels, fiber optics, lenses, and protective covers. Specialty glasses with tailored refractive indices and dielectric properties are crucial for high-performance devices, laser systems, and medical imaging equipment.

Glass’s aesthetic appeal is showcased in decorative art, mirrors, lighting fixtures, and tableware. Its ability to be colored, etched, or textured makes it a favorite medium for artists and interior designers. Glass mirrors and custom glass installations add elegance and functionality in both residential and commercial environments.

Looking for application-specific glass products? Browse our directory to find glass fabricators specializing in your industry—whether it’s automotive, architectural, laboratory, or electronics.

When evaluating glass for your project, consider factors such as thickness, strength, heat resistance, and optical clarity. For instance, glass tubes and laboratory glassware require superior chemical resistance and precise dimensional tolerances, while architectural glass must meet strict safety and energy efficiency standards.

For more detailed technical guidance on glass selection for your application, ask our experts or request a consultation with a leading glass manufacturer.

Care for Glass Products

While glass is engineered for durability, proper care and maintenance are essential to ensure long-term performance and safety. Whether you’re using glass in a laboratory, industrial, or residential setting, following best practices helps preserve its clarity and structural integrity.

Preventing Mechanical Damage: Even tempered and laminated glass can develop micro-cracks or chips if subjected to repeated mechanical shocks or improper handling. Avoid stacking glassware or panels without protective padding, and use appropriate carriers during transport and installation.

Mitigating Thermal Shock: Rapid temperature changes can cause glass to crack or shatter, especially in products not designed for thermal cycling. Always allow glassware and containers to equilibrate to room temperature before adding hot or cold substances. For applications exposed to extreme heat, select borosilicate or quartz glass for optimal thermal resistance.

Cleaning and Storage: Maintain glass surfaces using non-abrasive, pH-neutral cleaners to prevent damage to coatings or decorative finishes. Store glass in clean, dry environments away from corrosive substances and environmental contaminants, such as plaster dust or construction runoff, which can degrade coatings over time.

For more care and maintenance tips, explore our resource library or connect with a professional glass supplier for product-specific recommendations.

Considerations Regarding Glass Manufacturers and Suppliers

Choosing the right glass fabricator or supplier is a critical step in ensuring the success of your project—whether you require custom glass solutions, architectural glazing, or industrial components. When researching potential partners, keep the following factors in mind:

- Certification and Accreditation: Work with certified glass manufacturers who adhere to industry standards established by professional organizations such as the Glass Association of North America (GANA). Accreditation ensures product quality, safety, and regulatory compliance.

- Sustainability and Environmental Responsibility: Prioritize suppliers who incorporate sustainable practices, such as recycling cullet (scrap glass) and reducing carbon emissions during production. Environmentally responsible glassmaking not only supports green building initiatives but may also yield cost savings in the long run.

- Customer Service and Support: Select suppliers with a proven track record of customer satisfaction, offering value-added services like design consulting, product sampling, technical support, and warranties. Strong partnerships ensure clear communication and responsive problem-solving.

- Logistics and Delivery Capabilities: Assess a supplier’s ability to meet your volume requirements, fulfill custom specifications, and adhere to production and delivery schedules. Reliable logistics are vital for large-scale construction, manufacturing, or export projects.

Are you evaluating multiple glass suppliers? Compare fabricators in our directory to find the best fit for your project’s timeline, budget, and technical requirements.

Choosing the Right Glass Fabricator

Selecting the ideal glass fabricator is a process that requires careful research and comparison. Our comprehensive directory is designed to simplify your decision-making by providing detailed profiles of leading glass fabricators, complete with information on their technical capabilities, certifications, and areas of expertise.

Use our built-in contact forms to request additional information, obtain quotes, or inquire about custom solutions. Our unique website preview tool enables you to quickly explore each fabricator’s offerings and specialties, helping you shortlist potential partners based on your project’s unique requirements.

For projects requiring multiple quotes, our RFQ (Request for Quote) form streamlines the process, allowing you to reach out to several fabricators at once and compare responses side-by-side. Whether you need a custom glass component, architectural glazing, or high-performance specialty glass, our directory connects you directly with the industry’s top manufacturers and suppliers.

Ready to get started? Browse our listings of glass fabrication companies or submit your RFQ today to receive competitive bids from trusted glass fabricators.

What makes glass different from other materials like metals and plastics?

Glass is an inorganic, amorphous solid with a disordered atomic structure similar to a liquid, yet it displays the hardness and brittleness of a solid. This unique combination gives it properties such as transparency, hardness, and resistance to chemical attack, setting it apart from metals, ceramics, and plastics.

What are the main processes involved in glass fabrication?

Glass fabrication involves processes like cutting, grinding, drilling, polishing, tempering, edging, painting, coating, sandblasting, and etching. These processes customize glass for different shapes, features, and performance requirements, enabling applications in construction, automotive, electronics, and more.

How is float glass manufactured?

Float glass is produced by floating molten glass on a bath of molten tin. Gravity and surface tension create perfectly flat, uniform sheets. The thickness is determined by the speed at which glass is drawn off the bath. This method is essential for making windows, mirrors, and solar panels.

What are the most common types of glass and their uses?

Common glass types include soda-lime glass (for windows and bottles), borosilicate glass (laboratory and cookware), fused silica or quartz glass (optics, high-temperature settings), lead glass (fine glassware, radiation shielding), and specialty glasses like low iron, wire glass, and fiberglass. Each type serves specific performance requirements in various industries.

What are the advantages of using glass in construction and industry?

Glass offers exceptional strength (especially when tempered or laminated), chemical and thermal resistance, high optical clarity and light transmission, customizability, low maintenance, and sustainability due to recyclability. These advantages make it ideal for architecture, electronics, laboratory equipment, and more.

How should glass products be cared for to ensure longevity?

Care for glass by avoiding mechanical shocks or improper handling, preventing rapid temperature changes, and using non-abrasive, pH-neutral cleaners. Store glass in clean, dry areas away from corrosive substances. These practices help maintain clarity and structural integrity over time.

What factors should I consider when choosing a glass fabricator or supplier?

When selecting a glass supplier, consider certification and accreditation, sustainability practices, customer service, and logistics capabilities. Choose fabricators who uphold industry standards, prioritize environmental responsibility, offer technical support, and reliably meet project requirements.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services