Glass fabrication includes a wide range of processes used to shape, configure, and design glass. It involves glass blowing, assembly, glass cutting, casting, extrusion, drawing, pressing, heat shrinking, and etching as well as glass repair and recycling. The manufacturing of glass products includes combining glass with other materials for framing and reinforcement. Read More…

S & S Optical has been leaders as glass fabricators in a variety of industries and markets for over 50 years. We offer a variety of different glasses to fit all of your needs. Also, we have a multitude of capabilities and services to offer-polishing, grinding, edging and more. To learn how we can fabricate your parts contact us today for a quote. We care about customers and quality service.

Established in 1947, we have been providing glass cutting using very precise tolerances in order to ensure that our products are among the best. Our skilled designers and technicians are available around the clock in order to work with you from design to delivery to ensure that you are receiving a product that will fit your needs perfectly! For more information on what we may be able to do for...

Founded in 1990, Technical Glass Products is a fabricator of Fused Quartz Glassware. We maintain a broad inventory of labware, flat stock, rod and tubes in addition to providing custom fabrication using state of the art equipment to suit your needs.

Glass cutting is a varied industry, and we have done it all for the past 50 years. We believe in manufacturing high quality glass products that will exceed customer expectations every time.

More Glass Fabricator Manufacturers

The processes for fabricating glass are specifically chosen to fit the delicate nature of glass, using methods that ensure the quality and durability of glass products. Various fabrication methods require additional mechanical processes such as machining, grinding, finishing, and bonding, which increase the sturdiness of the glass products.

Three of the most common forms of glass fabricating are eyeglasses, telescopes, and prisms, items that have to be manufactured with the greatest amount of precision and accuracy. Of the three products, eyeglasses and telescopes require the greatest amount of care since they must be ground to exacting standards.

Types of Glass Fabrication Processes

Due to the delicate nature of glass, processes used to shape it have to be completed carefully and with close attention to detail. Depending on the needs of the product, the fabrication method can be very aggressive and invasive or slow and precise. Aside from its use as windows, glass has a varied number of applications, from aesthetic decorations to industrial and manufacturing uses.

Glass Blowing

The process of glass blowing consists of using a tube to blow air into molten glass, a process that has existed for thousands of years. As air is forced into the molten glass, it takes the form of a cylinder. During the process, the cylinder has to continually receive air and be heated such that it can be shaped and formed. Once appropriately formed, the shaped glass piece is removed from the blowing tube and allowed to cool.

Glass blowing begins with the creation of a batch, which is the ingredients for glass that have been mixed in preparation to be placed in a pot in a furnace. Using a process referred to as charging, the batch is melted at temperatures exceeding 2000 °F (1100 °C). A gaffer, or chief glassblower, uses a pipe made of steel or iron to pull a gob of molten glass from the pot and place it on the end of the tube.

As the gaffer blows through the tube, they slowly create a bubble in the glass. Additional glass can be added by dipping the blown glass back in the batch in the furnace. The gaffer uses a flat surface to assist in shaping and rolling the glass bubble. During the blowing process, the parison, blown glass, is turned round and round as it is shaped.

Glass Casting

Glass casting is like any other casting process. It involves pouring molten glass into a form or mold that is in the shape of the final product. The process is very similar to the one that is used with molten aluminum, steel, or other metals. The different types of glass casting include kiln casting, sand casting, lost wax casting, and open faced molding.

Glass Etching

Glass etching is a fabrication method for abrading or roughing the surface of a piece of glass to produce a design or pattern. There are several methods used to etch glass, which include acid etching, etching creams, abrasive blasting, mold etching, and frost etching.

Acid etching includes the use of a colorless acid to cut a design into the surface of a piece of glass. Mold etching is a form of casting where the etched design is included in the surface of the mold. Abrasive etching is a more aggressive etching process. It is a sand blasting method that uses high pressure air mixed with an abrasive compound to cut away the surface of the glass.

A technique that is similar to abrasive glass etching is laser glass etching. With the laser etching process, a laser beam makes contact with the glass surface and heats up its sand and metal content that creates chips or fractures to create a visual design.

Glass Cutting

Glass cutting is a precision process that involves making a score line or fissure on the surface of the glass that weakens the glass. Using a small amount of controlled force, a sheet of glass can be separated into two sections after being scored. The process of glass cutting can involve the use of a cutting wheel or CO2 laser cutter.

Mechanical or handheld glass cutters have a wheel that makes a consistent, uniform, and precision score line. The majority of glass cutting wheels are made of tungsten carbide, which are the highest quality and most durable. CO2 laser glass cutters use filaments to weaken the glass that is separated by heating and expansion. The precision of CO2 glass cutting has made it one of the most popular glass cutting methods.

The four glass fabrication processes described above are only four of the many methods used to produce viable glass products. Other methods include grinding, drilling, polishing, tempering, finishing, and edging, which are used to perfect and improve glass products.

Glass Fabrication Products

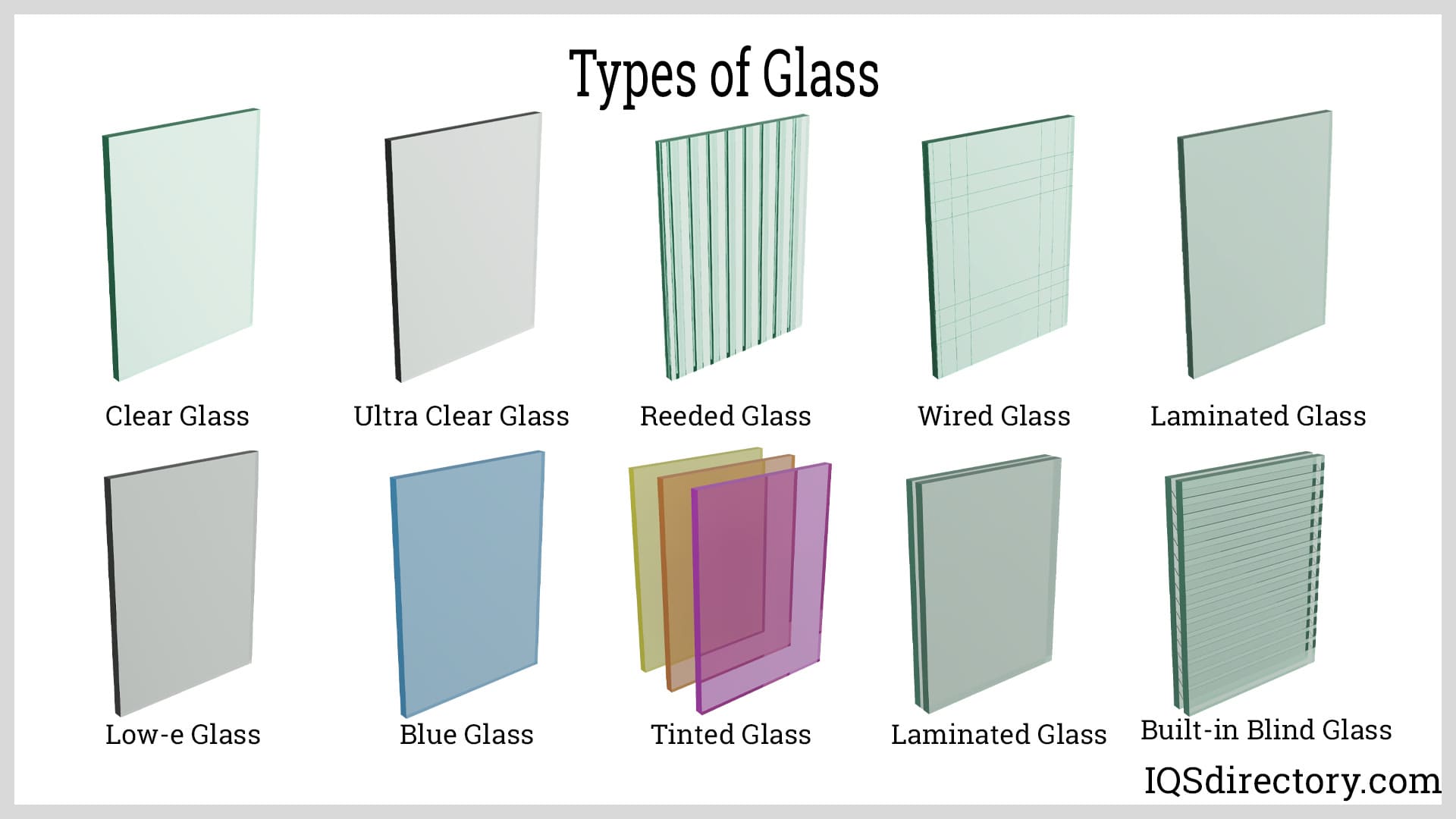

Glass fabrication is a generic term used to describe a wide assortment of products that are produced by working and treating raw glass. Each of the different processes are designed to produce necessary and functional components, parts, and assemblies for industrial applications. The number of products produced by glass fabrication is endless and covers a wide vector of parts, components, and implements. Some of the most common types of products produced by glass fabrication include drilled glass, polished glass, grooved glass, and sandblasted glass.

Strengthened Glass

Strengthened glass has high strength, thermal stability, and is exceptionally safe due various chemical treatments and thermal tempering. It has an impact strength that is three to five times higher than common glass with higher bending strength as well. Strengthened glass has the ability to withstand a wide range of temperature changes that are three times that of normal glass.

Laminated Glass

Laminated glass is made of two or more plies of glass that have a vinyl interlayer between each layer. When laminated glass is struck with force, it stays together, which qualifies it as safety glass. Additionally, laminated glass blocks 99% of UV rays, has sound reduction, can be shaped after lamination, and can qualify as bullet resistant. Since laminated glass can withstand direct impact, it is used for automobile windshields.

Optical Glass

The fabrication of optical glass is one of the more challenging aspects of the fabrication process. Optical glass requires the greatest amount of accuracy and precision since the smallest flaw significantly influences its quality. Lens made from optical glass can be flat, concave, convex, or achromatic to distribute light. Optical prisms are optical glass that have flat or angled surfaces used for refracting or distributing natural light.

Glass fabrication is a central part of the production and shaping of glass products for all industries that deal with or use glass as part of their products. It is an essential part of guaranteeing that glass products meet the quality stands required for their use.

Choosing the Right Glass Fabricator

To ensure you have the best outcome when choosing a glass fabricator, it is important to compare several glass fabricators using our directory of glass fabricators. Each glass fabricator has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the fabricator for more information or request a quote. Review each glass fabricator company website using our proprietary website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple glass fabricators with the same form.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services