It is most well known for its use in the automotive industry, although it is also used in a variety of applications which require stronger and safer glass than tempered glass. Read More…

S & S Optical has been leaders as glass fabricators in a variety of industries and markets for over 50 years. We offer a variety of different glasses to fit all of your needs. Also, we have a multitude of capabilities and services to offer-polishing, grinding, edging and more. To learn how we can fabricate your parts contact us today for a quote. We care about customers and quality service.

Established in 1947, we have been providing glass cutting using very precise tolerances in order to ensure that our products are among the best. Our skilled designers and technicians are available around the clock in order to work with you from design to delivery to ensure that you are receiving a product that will fit your needs perfectly! For more information on what we may be able to do for...

Founded in 1990, Technical Glass Products is a fabricator of Fused Quartz Glassware. We maintain a broad inventory of labware, flat stock, rod and tubes in addition to providing custom fabrication using state of the art equipment to suit your needs.

Glass cutting is a varied industry, and we have done it all for the past 50 years. We believe in manufacturing high quality glass products that will exceed customer expectations every time.

More Laminated Glass Manufacturers

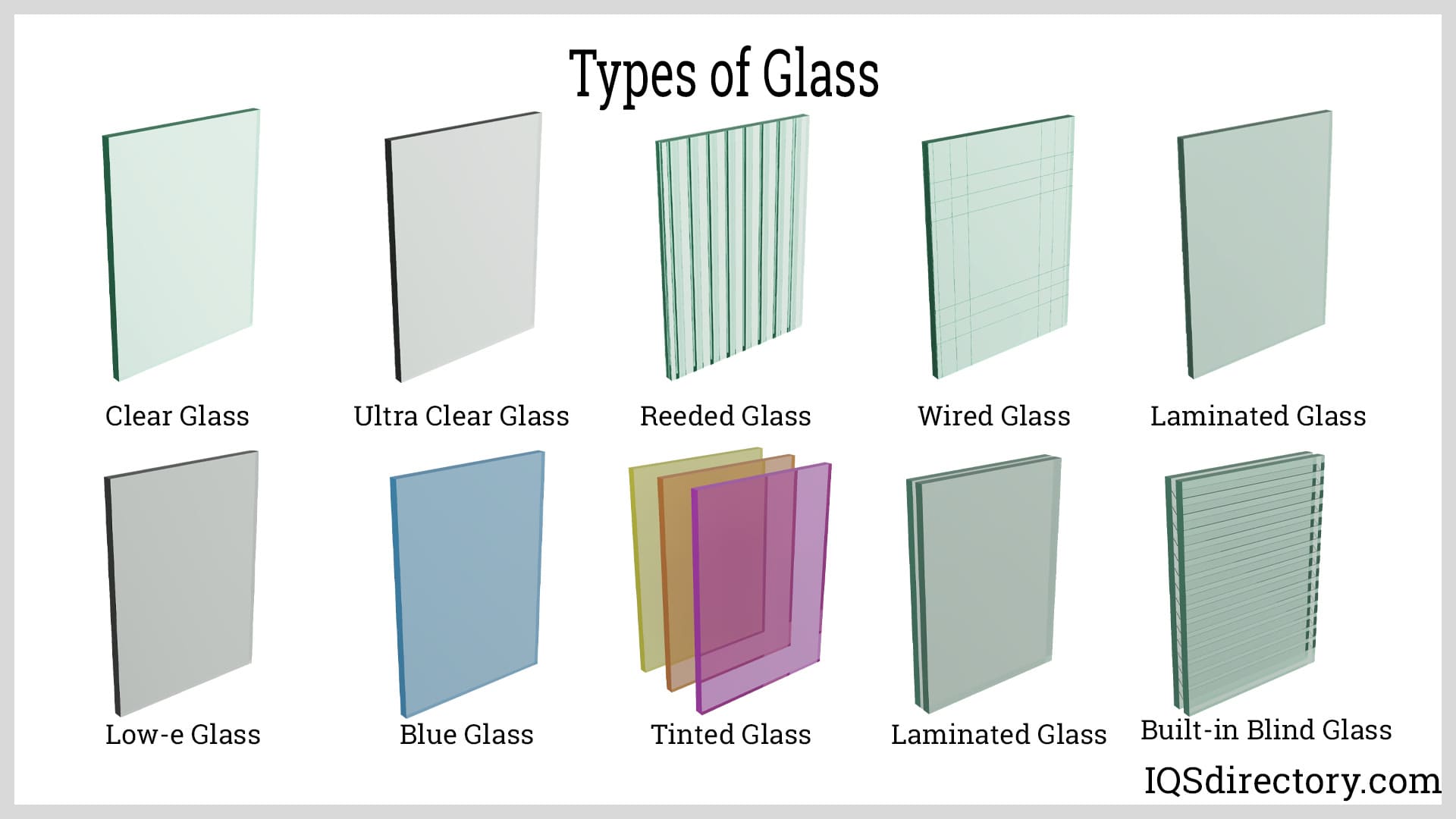

Laminated Glass: Properties, Applications, and Buyer’s Guide

Laminated glass has emerged as a leading solution in modern architectural, automotive, and security-focused applications due to its unique ability to remain intact even after heavy impact or breakage. This advanced glass product is specifically engineered to deliver enhanced strength, safety, and durability, making it a preferred choice for windshields, shower doors, cutting boards, and windows in high-security environments such as banks, airports, and jewelry stores.

What Is Laminated Glass?

Laminated glass is a type of safety glass composed of two or more layers of annealed glass bonded together with an interlayer—commonly polyvinyl butyral (PVB) or other specialty films. This configuration gives laminated glass its renowned ability to resist shattering and to hold together even after being broken. The result is a versatile glazing product that offers both protection and performance in a wide range of settings.

How Is Laminated Glass Manufactured?

To fabricate laminated glass, expert glass fabricators start by stacking sheets of annealed or heat-strengthened glass around a thin, flexible film of PVB or a similar binding interlayer. This assembly is then subjected to a combination of heat and pressure using specialized rollers. This process eliminates air bubbles and ensures an initial bond between the glass and interlayer. After rolling, the glass is placed in an autoclave or oil bath, where additional heat and pressure chemically bond the vinyl layer to the glass, further increasing the panel’s strength and integrity.

- Interlayer Materials: PVB (polyvinyl butyral), EVA (ethylene-vinyl acetate), SGP (SentryGlas Plus), and other specialty polymers tailored for specific requirements such as sound control, solar control, or ballistic resistance.

- Glass Types: Annealed, heat-strengthened, or fully tempered glass can be used in lamination, depending on end-use demands.

- Thickness & Configurations: Laminated glass panels are offered in a variety of thicknesses and can incorporate multiple layers to achieve bulletproof, hurricane-resistant, or soundproofing properties.

Key Properties and Advantages of Laminated Glass

The process of fabricating laminated glass imbues it with several critical properties and performance benefits that set it apart from monolithic or tempered glass options:

- Safety: Upon breakage, laminated glass fragments adhere to the interlayer, reducing the risk of injury from flying shards. This characteristic is crucial for applications near people or in high-traffic areas.

- Security: Laminated glass is much more difficult to penetrate than standard glass, often taking up to ten times longer to break through. It can deter forced entry, smash-and-grab theft, and vandalism, making it ideal for storefronts, display cases, and secure facilities.

- Impact Resistance: The combination of glass and interlayer provides superior impact resistance, allowing laminated glass to withstand high-velocity impacts from debris, tools, or even bullets when specially engineered.

- Sound Reduction: The interlayer dampens sound transmission, making laminated glass an excellent choice for soundproof windows in offices, studios, or residential buildings along busy streets or flight paths.

- UV Protection: Laminated glass can block up to 99% of harmful ultraviolet (UV) radiation, protecting interiors, furniture, and artwork from fading.

- Storm and Disaster Resistance: Laminated glass is widely used in hurricane impact windows, tornado-resistant glazing, and earthquake-safe building designs due to its ability to remain intact under extreme forces.

- Versatility: Available in clear, tinted, patterned, and decorative finishes, laminated glass can be customized to meet aesthetic, privacy, or branding needs.

Why Choose Laminated Glass Over Tempered Glass?

While tempered glass is valued for its strength and ability to break into small, harmless pieces, laminated glass offers an additional layer of safety and security. Tempered glass is frequently used for car side windows and interior partitions, but for windshields, overhead glazing, and any area where maximum impact resistance is required, laminated glass is the superior option. Notably, even after being chipped, punctured, or fractured, laminated glass remains in place, thanks to its resilient interlayer—making it the trusted standard for automotive windshields and critical infrastructure.

Common Applications of Laminated Glass

Thanks to its unique properties, laminated glass is increasingly specified in a diverse array of commercial, residential, and specialty applications:

- Automotive Windshields: Virtually all car windshields use laminated glass to protect passengers from impact, road debris, and potential ejection during accidents.

- Building and Architectural Glazing: Laminated glass is used for windows, skylights, curtain walls, balustrades, and glass facades in high-rise buildings and public spaces to enhance safety and security.

- Security and Bullet-Resistant Glass: Banks, airports, government offices, and jewelry stores install multi-layer laminated glass for increased resistance to burglary and ballistic threats.

- Soundproof Windows: Hotels, studios, and offices utilize laminated glass for its acoustic insulation properties, minimizing outside noise and improving occupant comfort.

- Shower Doors and Bathroom Partitions: Laminated safety glass is a premium choice for wet environments where slip hazards and breakage risks are high.

- Display Cases and Cabinets: Museums, galleries, and retailers rely on laminated glass to protect valuable items while offering maximum visibility.

- Railings and Balustrades: Laminated glass railings provide safety without obstructing views on balconies, decks, and staircases.

- Solar and Energy Applications: Specialized laminated glass is used in photovoltaic panels, greenhouses, and daylighting systems for its strength and light transmission qualities.

- Custom Uses: Laminated glass cutting boards, tabletops, and specialty furniture pieces offer a blend of durability, safety, and style.

How to Select the Right Laminated Glass for Your Project

Choosing the best laminated glass solution depends on several critical factors, each of which can impact performance, cost, and compliance with building codes or safety standards. Consider the following when specifying or purchasing laminated glass panels:

- Intended Application: Is your priority safety, security, sound control, or aesthetics? Determine the primary goal to select the right glass type, interlayer, and thickness.

- Performance Requirements: Do you need hurricane-resistant, bulletproof, fire-rated, or soundproof glass? Consult with a glass fabricator about the available options and certifications.

- Glass and Interlayer Thickness: Thicker glass and multiple interlayers increase resistance to impact and sound but may add weight and cost. Find the right balance for your needs.

- Compliance and Codes: Ensure your laminated glass meets local building codes, safety glazing standards (such as ANSI Z97.1, CPSC 16 CFR 1201), and insurance requirements.

- Aesthetic Considerations: Choose from clear, tinted, patterned, or decorative interlayers to match your project’s design vision.

- Budget and Lead Time: Custom laminated glass solutions may require longer lead times. Work with your fabricator to plan accordingly and optimize costs.

Need help determining the right laminated glass for your building or renovation project? Contact a professional glass fabricator to discuss your requirements and receive expert guidance on product selection, performance ratings, and installation best practices.

Frequently Asked Questions About Laminated Glass

- What is the difference between laminated and tempered glass?

Laminated glass consists of two or more glass layers with an interlayer that holds the pieces together when broken. Tempered glass, by contrast, is heat-treated to increase strength and shatters into small pieces upon impact. Laminated glass offers greater impact resistance and is safer for overhead and security applications. - How thick is laminated glass?

Laminated glass comes in a range of thicknesses, typically from 6.38 mm (1/4") up to 76 mm (3") or more for specialty applications. The thickness depends on the number of glass layers and the interlayer used. - Can laminated glass be cut or drilled?

Laminated glass must be cut or drilled before lamination. After lamination, it is challenging to modify without damaging the interlayer or causing delamination. - Does laminated glass block sound?

Yes, the interlayer acts as a sound barrier, making laminated glass one of the best choices for acoustic glazing and noise reduction. - Is laminated glass energy efficient?

Laminated glass can be combined with Low-E (low emissivity) coatings and insulated glass units (IGUs) for improved thermal performance and energy savings.

Comparing Laminated Glass to Other Glazing Options

When evaluating glass types for safety, security, or performance, you may wonder, “Should I choose laminated, tempered, or standard glass?” Here’s a quick comparison to help you make an informed decision:

| Feature | Laminated Glass | Tempered Glass | Standard (Annealed) Glass |

|---|---|---|---|

| Breakage Behavior | Holds together; remains intact | Shatters into small pieces | Breaks into large, sharp shards |

| Impact Resistance | Very high; can be bullet/hurricane resistant | High; not bullet resistant | Low |

| Safety | Maximum | Moderate | Minimal |

| Sound Control | Excellent (with sound-dampening interlayer) | Poor | Poor |

| UV Protection | Up to 99% | Low | Low |

| Applications | Windshields, security glazing, soundproofing, skylights | Side/rear car windows, doors, partitions | Picture frames, interior glass, low-risk areas |

Searching for the Best Safety Glass for Your Needs?

Explore our in-depth guides on tempered glass, bullet-resistant glass, and custom glass fabrication to compare features, costs, and ideal use cases. Not sure what you need? Ask our experts for tailored recommendations based on your project, safety, and performance requirements.

Benefits of Laminated Glass for Building Owners, Architects, and Contractors

Laminated glass is more than just a safety feature—it’s a multi-functional solution that delivers value across the entire lifecycle of a building or vehicle. Here’s why professionals consistently specify laminated glass in their designs:

- Regulatory Compliance: Meets strict safety codes and glazing regulations for schools, hospitals, and public spaces.

- Reduced Liability: Limits injuries from breakage, minimizing legal and insurance risks.

- Enhanced Security: Delays forced entry and provides peace of mind for property owners and occupants.

- Flexible Design: Supports creative architectural concepts through custom colors, patterns, and embedded graphics.

- Longevity: Offers outstanding durability and resistance to weathering, corrosion, and fading.

- Lower Maintenance: Less frequent replacement and easy cleaning compared to other glazing options.

- Occupant Comfort: Improves acoustic and thermal comfort, contributing to higher building value and tenant satisfaction.

Are you a contractor, architect, or building manager seeking high-performance safety glass? Request a quote or product sample from a trusted glass fabricator to see how laminated glass can elevate your next project.

How to Buy Laminated Glass: Step-by-Step Guide

- Identify your project requirements: Specify size, thickness, performance criteria (e.g., hurricane, bullet, fire, or sound resistance), and any aesthetic preferences.

- Consult with a reputable glass fabricator to discuss options, pricing, and lead times.

- Review product data sheets and request samples to confirm clarity, tint, and edge quality.

- Ensure compliance with relevant codes and standards for your location and application.

- Place your order and coordinate delivery and installation with certified professionals to guarantee performance and warranty coverage.

Ready to Upgrade to Laminated Glass?

Whether you’re renovating a commercial property, designing a new home, or enhancing vehicle safety, laminated glass offers unmatched protection and versatility. Explore our full range of laminated glass products or contact our team for expert advice on specifications, installation, and maintenance.

Summary: The Ultimate Solution for Safety, Security, and Performance

Laminated glass stands at the forefront of modern glazing technology, delivering superior safety, strength, and design flexibility for a wide spectrum of applications. From hurricane-resistant windows to bulletproof barriers and sound-reducing facades, laminated glass is engineered to meet today’s demanding building and automotive standards. Its ability to cohere after experiencing great force or breakage makes it indispensable for windshields, shower doors, cutting boards, and windows in buildings requiring extra protection such as banks, airports, and jewelry stores.

Whether you need impact-resistant glass for hurricane zones, soundproofing for urban environments, or decorative safety glass for architectural features, laminated glass is a worthwhile investment for any project that values safety, security, and style.

Still have questions? Explore our resources or talk to a glass expert to find the optimal laminated glass solution for your needs.

Adhesives

Adhesives Alumina Ceramic

Alumina Ceramic Ceramic

Ceramic Glass

Glass Graphite

Graphite Lubricants

Lubricants Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services